To get a quick price quote, please submit this price request form after filling out your required specifications. Our sales representative will shortly get in contact with you.

Unlock the potential of your products with our unrivaled packaging solutions tailored to your industry and specific product needs.

Dimensions

Dimensions

|

All custom sizes & shapes |

Min.quantity

Min.quantity

|

50 Boxes ( Hardproof Sample Option Available ) |

Default process

Default process

|

Die cutting, gluing, scoring, perforation |

Printing

Printing

|

Cmyk, pms, no printing |

Options

Options

|

Custom window cut out, gold/silver foiling, embossing, raised ink, pvc sheet. |

Turn around time

Turn around time

|

10-12 business days , rush |

Paper stock

Paper stock

|

210gsm-1400gsm (240gsm, 260gsm, 300gsm, 350gsm, 420gsm, 520gsm, 620gsm, 1000gsm, 1400gsm) |

Proof

Proof

|

Flat view, 3d mock-up, physical sampling (on Request) |

Delve into the World of Cereal Boxes: An all-encompassing Guide

Cereal box packaging need to be well-designed and sturdy for preservation of freshness and protection of contents. A sturdy cereal box helps convey quality and reliability to consumers. The durability of these boxes reflect brand image and therefore CBO focuses on meticulous process of manufacturing and designing these boxes for your brand.

We focus on functionality, quality and outlook of these boxes. Let's go on a journey through different types of cereal packaging and see why CBO excels compared to competitors in the UK.

The Process of Cereal Box Manufacturing

Cereal packaging are finely made to preserve the breakfast and other snacks and cereals and they play an integral role in maintaining the fine quality and freshness of cereals. These also work as marketing tool and help in brand promotion.

1. Design Phase: The design phase is the start of our process of designing the cereal box, where the design, structure and graphics are pictured. This phase will be concerned with the details such as the box dimensions, the material selection, the printing method, and other accessories like windows and inserts.

2. Material Selection: The packaging of our boxes is largely made from cardboard or paperboard materials. These materials are selected in terms of their sustainability and ease of printing, yet they are compatible with bright colors and prints. The thickness and type of the material may differ with regard to safety and aesthetic for the desired purpose of protection or presentation.

3. Printing: After the design is completed, the printing process then counterparts using high-end printing methods, such as offset printing, screen prints or digital printing. We print the graphics, branding elements, nutrition information, and other text on the box.

4. Die Cutting: After printing, the flat sheets of material are die-cut to fit the required shapes and dimension of the cereal boxes. This operation includes the utilisation of a particular instrument known as a die that cuts out the box panels, flaps, and other elements with utmost precision.

5. Folding and Gluing: The die-cut sheets are scored and glued following the lines on the surfaces of the sheets in order to create the three-dimensional shape of the custom cereal packaging. Machines are typically used in such a process so that the boxes can be folded and glued very quickly and very accurately, meaning that the quality is uniform across the whole production line.

6. Quality Control: Quality control steps are applied during the production stage to make sure that every cereal box meets the expected standards of strength, print, and the overall look. Inspections can be carried out throughout the process, whereby defects or issues are recognised and straightened out.

7. Packaging and Shipping: After these boxes by CBO have been produced and checked, they are packed in bigger cartons or pallets for transportation to the distribution centres, the retailers, or the customer's location. Correct packaging and handling protocols are adhered to in order to avoid destruction while in transit and storage.

That is how our cereal box packaging is made in multiple steps involving design, material selection, printing, die cutting, folding and glueing, quality control, and packaging. Every stage is indispensable in the process of making cereal box of top-notch quality which meets the product's functional and aesthetic requirements.

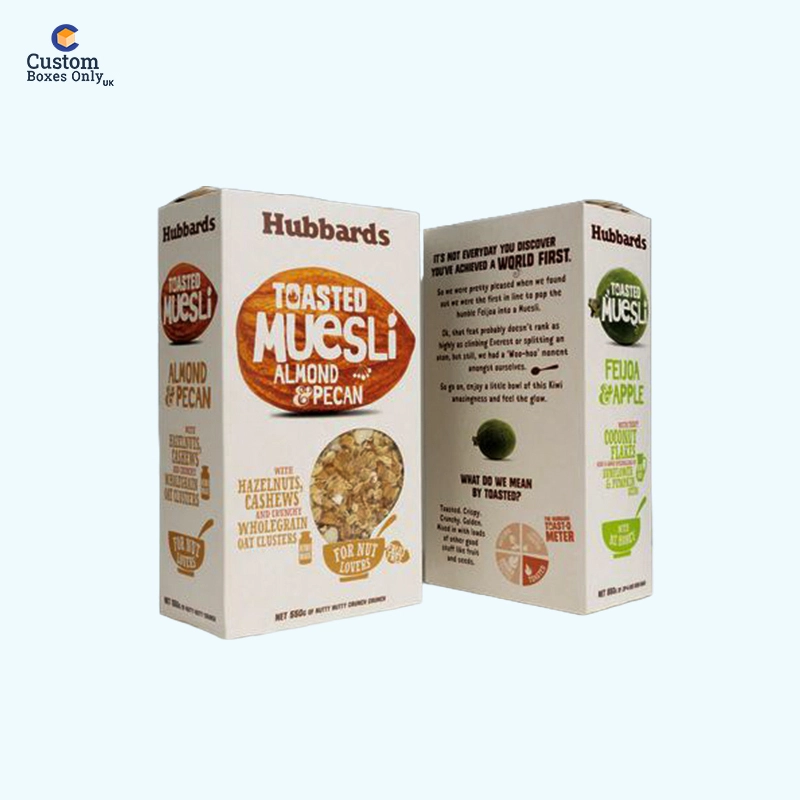

Breakfast Bliss Packaging Premium

Characterised with precision, our cereal box is perfect, making us the leaders in the UK market. Made of e-flute rigid material and possessing a unique interlock system, these boxes ensure that your favourite cereals arrive safe and sound. Custom cereal boxes include both professionalism and can cast a fresh image in the minds of your customers because of unique packaging and printing.

Luxury Printed Cereal Boxes for Brand Identification

Our custom-printed cereal boxes are a strong brand ambassador, always being the vehicle that drives your brand and increases its visibility among consumers. Unique in their design and made with attention and creativity, each box has optional handles and inserts for additional ease in handling. Made from solid cardboard and coming together with a unique interlocking system, these branded packages have a sense of tough strength and reliability. We will customise your cereal box with your brand name, logo, and colours to make the experience unforgettable for the consumers.

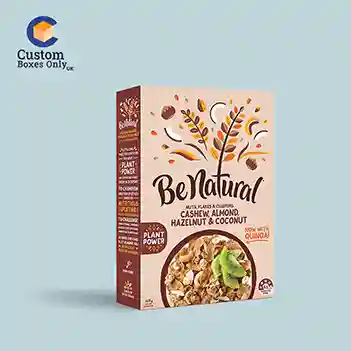

Customised Packaging Solutions for All Occasions

CBO’s printed cereal boxes serve various needs and tastes, including home breakfast, snacks on-the-go, or festive ones. Select among the different packaging possibilities including standard boxes for daily use, display packaging to display delicious morsels, and multi-pack boxes for larger quantities. In turn, our luxury packaging is designed for adding elegance to any kind of event or occasion.

Why Choose CBO?

We present a variety of customisable styles, sizes, vibrant colours, and ecological options to choose from at CBO. Opt for high-tech printing methods like CMYK and PMS colours to improve your packaging and decorate boxes with foil stamping and embossing for extra visual attraction. Benefit from a free delivery facility and cereal boxes wholesale savings without any minimum order limit. Due to the ease of our ordering process, the delivery of your boxes to your doorstep takes between 6-8 business days. Moreover, the shipping is entirely free within the UK.

Place Your Order Today

CBO is the starting point of your journey to outstanding cereal box packaging. With expert designers and manufacturers at Custom Boxes Only, getting your personalised and printed cereal boxes wholesale is easy. Order custom-made cardboard cereal box packaging at cheaper rates only from us by visiting our website. We have a vigilant customer service team that is available to assist you with any relevant queries regarding your order.

Food & Beverage Packaging

Food Safe Coating

Gloss Lamination

Food & Beverage Packaging

Metallic Coating

Pearlescent Coating

Soft Touch Coating

UV Coating

Matte Lamination

Embossing and Debossing

Metallic Foil Stamping

Spot UV

Window Cut-Out

PET Window Patching

Our Best Sellers